Home » Industry 4.0

Articles Tagged with ''Industry 4.0''

Quality in Automation | Industry 4.0

Connected Quality Is the Secret Sauce to the Fulfillment of Industry 4.0

Integrating QC and QA can mitigate product quality risk and empower smarter factories.

April 6, 2023

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

Vision & Sensors | Automation

Metrology Automation Finally Arrives

The smart start to metrology.

December 7, 2022

Software & Analysis

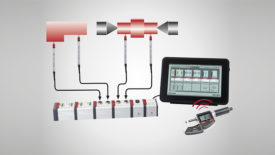

Integrating QC Measurement Data Into Manufacturing Systems

The best wireless data collection systems can dramatically increase productivity, remove the potential for errors, provide complete documentation and automate the data acquisition process.

October 10, 2022

NDT | Back 2 Basics

Robotic Computed Tomography Ready for NDE 4.0

Besides the automation of a CT system for NDE 4.0, it is very important to digitize the whole process for NDE.

August 8, 2022

Measurement

Submicron Displacement and Thickness Measurements with Confocal Sensors

Confocal chromatic measuring systems provide highly accurate distance, position, displacement and thickness measurements.

July 1, 2022

What Is a Digital Twin?

Digital twin technology helps organizations to use real-time data, mockups, algorithms, and AI to create a virtual depiction of a physical object, process, or service.

May 9, 2022

Measurement

It is Never Too Late to Teach an Old Custom Gage New Tricks

There are myriad ways to breathe new life into existing gages without the need to invest in new gaging.

March 8, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing