Home » Industry 4.0

Articles Tagged with ''Industry 4.0''

New Software Technology Advances the Practicality of Quality 4.0

It’s time to close the gap between Quality 4.0 and Industry 4.0.

October 8, 2019

The State of Sensors in the Industrial IoT

Better quality is possible with IO-Link and machine learning.

August 8, 2019

NDT and Industry 4.0

How Industry 4.0 is affecting NDT in manufacturing, and a brief look into different technologies that affect NDT.

April 1, 2019

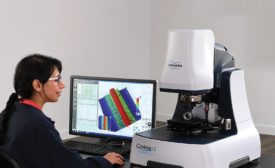

As Automation Grows, Microscopes Evolve

Industry 4.0 advances a variety of microscopy solutions.

April 1, 2019

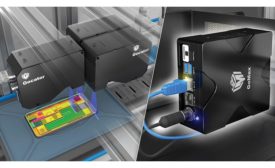

Q&A: 3D Smart Sensors, Deep Learning, and The Future of Automated Quality Control

The CEO of LMI Technologies describes how 3D sensors are integral to a new era of quality.

March 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing