Home » cobots

Articles Tagged with ''cobots''

Optipro enhances their world-class optics manufacturing systems using new tools for robotic machine tending and small part measurement.

Read More

Quality in Automation > Collaborative Robots

Collaborative Robots Improve Quality

With the growth of collaborative robots, manufacturers gain a valuable tool.

April 4, 2020

Robot, Robots, Everywhere!

Robots are the go-to tool for manufacturers wanting to increase throughput along with quality and efficiency.

April 1, 2019

Can You Save Time and Money by Automating your Quality Processes?

Whether you are looking at industrial robots or cobots, automation can be a great solution.

March 1, 2019

QUALITY WEB EXCLUSIVE

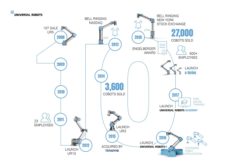

Universal Robots Celebrates 10 Year Anniversary of Selling the World’s First Commercially Viable Collaborative Robot

Universal Robots marks a decade of pioneering collaborative robots, now the fastest-growing segment of industrial automation.

January 3, 2019

INDUSTRY HEADLINE

Danish Robot Equipment Company OnRobot Acquires Purple Robotics

September 20, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing