Home » deep learning (DL)

Articles Tagged with ''deep learning (DL)''

Vision & Sensors | Optics

Proper lighting design is essential to assure a successful machine vision project. Ignoring this is one of the most common causes of machine vision project failures.

Read More

Vision & Sensors | Trends

Trends in the Machine Vision Market

Observations on the market and the technologies that could be the next to impact applications in automation.

January 4, 2023

Vision & Sensors | Trends

Machine Vision Developments Drive Automation Upward

As business needs grow and transform over time, suppliers continue pushing machine vision technology forward.

December 9, 2022

Vision & Sensors | Analysis

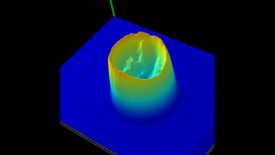

Understanding The Value Proposition For Deep Learning in Machine Vision

Deep learning software represents a powerful tool in the machine vision toolbox, but one must first understand how the technology works and where it adds value.

September 1, 2022

Vision & Sensors | Vision

Developments in Vision Systems: Deep Learning, Rapid Development Environments And Factory Integration

The move to Industry 4.0 requires better connectivity to enable data trasnfer and sharing between all components within the factory structure.

May 1, 2022

Vision & Sensors | Trends

The Place for Deep Learning in Industrial Machine Vision

Deep learning is an "add on" to traditional machine vision. It does not eliminate the ability to handle a range of tasks using traditional tools.

May 1, 2022

Vision & Sensors | Trends

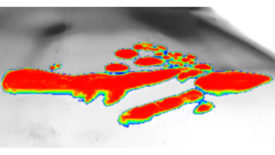

Advanced Imaging And Deep Learning Technologies Execute Critical Packaging Inspection

While machine vision applications have been highly successful for decades using "analytical" vision tools, deep learning is able to successfully solve very complex classification and object detection problems with ease.

March 1, 2022

Vision & Sensors | Systems Integration

Machine Vision Systems Integration: Deep Learning

An introduction to when and how to incorporate deep learning in industrial automation applications.

September 1, 2021

The Hybrid Approach

Combining the best of traditional machine vision and deep learning.

January 12, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing