Home » software & analysis

Articles Tagged with ''software & analysis''

Software

Regular use of FMEA leads to continuous improvements in processes and products. By proactively addressing potential issues, it enhances reliability, safety, and overall quality.

Read More

Software & Analysis

Don’t Touch That Process-Improvement Dial!

Despite your best intentions, you cannot improve a process without first differentiating between common and special causes.

March 21, 2024

New Product

Kitov.ai Software Platform for Improved Automated Visual Inspections

March 18, 2024

Quality Headline

Flexxbotics Appoints Marc Lind as Chief Strategy Officer, Chief Marketing Officer

March 5, 2024

New Product

Emergent Vision Technologies Plug-ins for eCapture Pro Software

February 5, 2024

Quality Headline

MVTec Hires Schulmeyer as Product Manager for MVTec MERLIC

January 29, 2024

Quality Headline

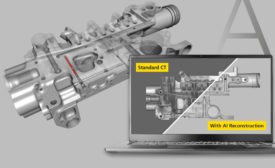

Hexagon’s Volume Graphics Software Wins Top Industry Award in Scanning, Metrology Category

December 20, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing