Measurement

Case Study

Inspection Arsenal fixturing transforms student part inspection at Van Buren Tech in Lawrence, MI.

Read More

Measurement

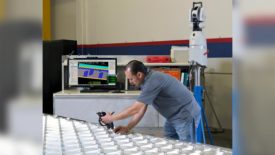

Maximizing Precision: How to Care for and Integrate Your Handheld Gages

Quality control is crucial for meeting high product standards, and handheld gages are key to achieving such precision. But how exactly do these tools ensure accurate measurements?

February 19, 2024

Quality 101

The Next Dimension of Precision: Integrating Rotary Tables into Coordinate Measuring Systems

The accuracy and reliability of CMMs and PCMMs are foundational to quality.

February 16, 2024

Measurement

Embracing Quality 4.0: Precision Gaging Transforms Manufacturing with Data-Driven Precision

Quality engineers are uniquely positioned to leverage this data because they have been analyzing and interpreting manufacturing data for decades.

January 29, 2024

Measurement

Measuring Thickness Using Model-Based Metrology Software

Measuring and verifying the thickness of features is more critical than ever before.

January 26, 2024

Measurement

Unraveling the Tom Brady Deflategate

A comprehensive analysis of measurements, traceability, and uncertainty in the Tom Brady controversy.

January 15, 2024

Measurement

The Crucial Role of Support and Service while Investing in Multi-Sensor Metrology Equipment

In today’s fast-paced industrial environment, the right support and service can make all the difference between a successful investment and a costly disappointment.

December 29, 2023

Measurement

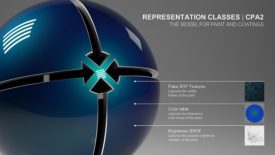

Why Digital Workflows Require More Than Digital Color

If you only digitize color using spectral data, you are missing valuable data required for the digital design and visualization workflow.

December 29, 2023

Measurement

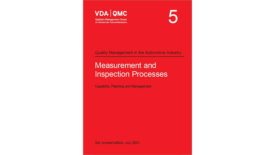

The new VDA Volume 5 – Obligation and Opportunity

Too much measurement uncertainty leads to incorrect conformity decisions, incorrect assessment of machines and production processes, poorer process quality and thus, increased production and testing effort.

December 29, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing