Test & Inspection

NDT | Training

Remote Visual Inspection has Provided Key Inspection Data While Maintaining Safety for its Operators.

Read More

NDT | Back 2 Basics

The Basics of Digital X-Ray Inspection

Conventional Radiography Will Continue to Have a Pace in NDT, but Digital Radiography is the Future

June 7, 2021

TEST & INSPECTION

Changing Face of Additive Manufacturing Inspection

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

June 1, 2021

Test & Inspection

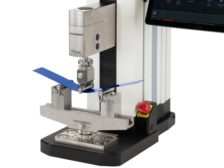

Navigating Supply Chain Challenges with Force Testing

Recent advancements in force measurement equipment allow quality professionals to better handle unpredictable testing demands.

May 5, 2021

2.5D Vision Hits Sweet Spot for Collaborative Applications

Automation can be deployed without having to redesign large parts of your facility.

April 8, 2021

VISION GUIDED ROBOTICS

Best Practices for Implementing Vision Guided Robotics

An important first step in any application is a thorough project evaluation prior to system design and implementation.

April 8, 2021

Six Ways Six Degrees of Freedom Probe Technology And Laser Trackers Can Enhance Your Business

In general 6DoF probes meet the dynamic measurement, speed, and accuracy requirements of the most challenging industrial applications.

April 7, 2021

Quality Headline

KULR Partners With Andretti Technologies to Bring Mars Rover Technology to EV Motorsports

March 24, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing