Test & Inspection

Illumination: The Third Pillar of Imaging System Design

Illumination is an often-overlooked yet crucial aspect of vision.

September 1, 2019

How to Choose a Vision Lighting Technique

5 common vision lighting techniques and 5 critical questions to ask.

September 1, 2019

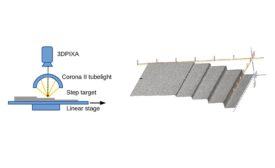

3D Stereo Camera Repeatability Measurement

Understand the process to determine measurement repeatability of a stereo 3D camera.

September 1, 2019

Grip and Fixture Solutions for Force Testing

Many factors come into play when choosing the right mounting hardware to ensure the specimen is properly aligned.

September 1, 2019

Get Started with 3D Scanning

How to select a 3D scanning technology for your application.

September 1, 2019

Quality Headline

Validate Worker, Student Inspection Skills with New NIMS Credential

August 26, 2019

Quality Headline

SGS Helps Emergency Medical Equipment Manufacturers Understand IEC 60601-1-12

August 26, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing