Test & Inspection

Setting up flaw detection is not without its challenges.

Read More

Strain Measurement Techniques for Composites Coupon Testing

The measurement of strain is a key requirement in tests to determine and monitor tension, compression, and shear properties.

November 5, 2015

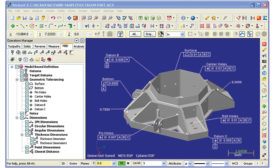

3-D Model-Based GD&T for Inspection

A key element of model-based definition.

November 4, 2015

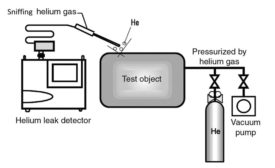

Everything Leaks

Leak detection is an art form that requires, in some cases, special equipment, training and patience.

October 12, 2015

Ultrasonic Testing of Metal Bars and Tubular Products

Whether manual, automated, or phased array, ultrasonic testing can help manufacturers of bars, tubing, and related metal products to ensure product quality and customer satisfaction.

October 12, 2015

Thread Ring Realities

ANY ONE OF THESE ELEMENTS COULD MEAN A GAGE IS OUT OF TOLERANCE.

October 2, 2015

Tensile Testing Machine Basics

Learn more about testing solutions available today.

October 1, 2015

INDUSTRY HEADLINE

Rudolph Acquires Inspection Technology of Stella Alliance

September 29, 2015

INDUSTRY HEADLINE

GE Introduces First Industrial CT Operator Training Course

September 14, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing