Software

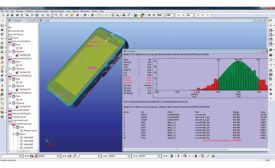

Closed Loop Manufacturing: CAD Driven Supplier Quality

CAD simulation benefits both OEMs and suppliers, and incorporating supplier measurement data gives powerful tools for quality improvement.

February 8, 2018

ERP Software: Get Thee to the Cloud—or Get Left Behind

ERP software vendors still provide on-premise and mixed ERP options for manufacturers, but the future is in the Cloud.

January 8, 2018

INDUSTRY HEADLINE

GE Additive Acquires GeonX to Strengthen Software Simulation Capabilities

November 16, 2017

INDUSTRY HEADLINE

Savigent Software Announced as First National Member of Clean Energy Smart Manufacturing Innovation Institute

November 13, 2017

INDUSTRY HEADLINE

Greenlight Guru Extends Platform with New Product to Streamline Post-Market Quality Processes

November 8, 2017

The Volume of Data Is Increasing

One of the primary drivers for the amount of data available today stems from integrated systems.

November 6, 2017

INDUSTRY HEADLINES

Frost & Sullivan Recognizes ComplianceQuest Innovation in Advancing Modern Cloud Enterprise Quality Management Solutions

October 11, 2017

From Paper and Pencil to Industry 4.0: Revealing the Value of Data through Quality Intelligence

For manufacturers to realize the full power of quality and the data behind it, they must embrace the technology available.

October 10, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing