Software

Software & Analysis

A combination of hardware and software make up any vision system.

Read More

How Manufacturers Can Make the Most of Their Data

The right SPC software helps leaders earn solid returns on their quality management software investments.

October 11, 2021

Software & Analysis

Gaging Software’s Changing Role

As manufacturers become leaner and integrate metrology in innovative ways, openness and interoperability are paramount.

October 8, 2021

Software & Analysis

Leveraging New Technologies to Future-Proof Your Quality Management System

Consider the following technology innovations available today and in the Near Future

September 1, 2021

Software & Analysis

Building Customer Loyalty Starts with Great Quality Management

There is no Denying that Implementing a Digital Quality Management System Helps Companies Avoid Risk and Lower Costs.

August 15, 2021

Quality Headline

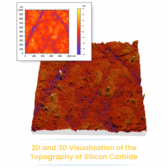

Covalent Metrology Partners With Digital Surf to Bring Analytical Solutions to Instrument Users

August 2, 2021

Software & Analysis

The Evolution of Quality Management Systems Software

From the CEO to the Manufacturing Floor, Access to Data Empowers the Organization to Improve.

July 8, 2021

The Advantages of Automated SPC Software, by Industry

The advantages to SPC can be applied differently, depending on the field you’re in.

June 14, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing