Quality 101

Quality 101

The mechanical testing of composite materials involves a range of test types, a plethora of standards, and the need to condition and test in a variety of different environments.

Read More

Quality 101

Choose and Use the Proper Thread/Ring Gage

Ring gages are used for comparative gaging as well as for the checking, calibrating or setting of gages in a wide variety of industries.

June 3, 2014

Quality 101

In-Process Air Gaging

The terms in-process and air gaging may not immediately sound like they go together, but there are advantages to this method.

May 1, 2014

Quality 101

The Rundown on Handheld Gages

Handheld gages are mainstays in quality manufacturing environments, although they are still see seeing improvements—with more on the horizon.

April 1, 2014

Quality 101

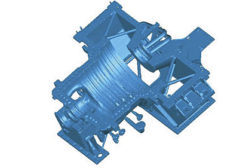

3-D Measurement: The Basics

While CMMs are still industry staples, the versatility, quickness and ease-of-use of a 3-D scanner makes it most manufacturers’ measurement tool of choice.

March 3, 2014

Improve Inspection with Opto-Digital Microscopy

Accessible digital imaging technology is ideal for advanced quality control applications across a variety of industries.

February 3, 2014

Shaft Measurement 101

Shaft measurement tools have proven their reliability at manufacturing sites around the world.

January 7, 2014

Quality 101

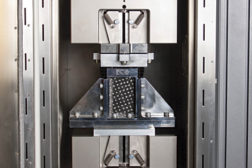

Force Gages 101

A force gage is an invaluable tool for a range of applications

November 6, 2013

Quality 101

Measure Your Needs for the Proper Height Gage

Selecting the right gage for the right job.

October 30, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing