Quality 101

Quality 101

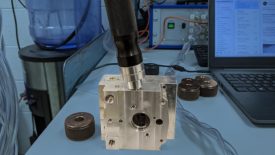

There are many different parts of a universal testing machine that can be partially or fully automated depending on the specific needs of your lab.

Read More

Quality 101

Automation’s Growing Role in Universal Testing

The pandemic proved just how important universal testers are to quality. As staff shorages endure, automation is keeping this technology on point.

May 10, 2023

Quality 101

Learns from ISO 9001:2015

Having conducted well over 700 audits, I've noticed some patterns.

March 29, 2023

Quality 101

Taper Pipe Thread Inspection, NPT

If you take care of your gages, they will take care of you and the parts you manufacture.

March 2, 2023

Quality 101

How to Launch a Digital Twin Strategy for Quality Control

Producing a digital twin that opens opportunities for quality control improvements requires accurate, high-resolution data.

February 9, 2023

Quality 101

Nondestructive Testing Using the Resonance Acoustic Method

RAM is a volumetric approach and evaluates the whole part, both for internal and external structural flaws, metallurgical deviations, and consistency.

December 15, 2022

Quality 101

Air Gaging Basics: The 4 W’s

What, who, why, and where of air gaging.

November 23, 2022

Quality 101

Automation: Should Manufacturers Fight Or Flight?

Despite its praised benefits, many manufacturers still decide against automation. But does that decision stem from fear?

August 16, 2022

Quality 101

Know Your True Cost of Quality with Integrated ERP

In the end, the true cost of quality comes down to the cost of making the part plus the cost of bad parts.

July 15, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing