NDT

Eddy current testing has typically been employed for surface and tubing inspections, but it can be employed for much more.

Read More

Latest Developments in Borescope Technology: Dual Camera Modules

Breakthroughs in materials, electronics and manufacturing techniques have led to innovations that have greatly expanded the capabilities of borescopes.

April 1, 2020

TFM Acoustic Influence Map

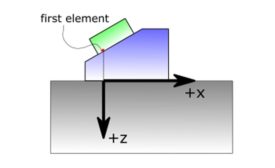

The total focusing method (TFM) is a synthetic aperture beam forming technique that has been under active development in the NDT industry over the past decade.

February 8, 2020

NDT Headline

Test Equipment Distributors Appoints Sengenberger Sales Rep for Midwest U.S.

November 18, 2019

Knapheide Saves Costs and Time in Nondestructive Vehicle Testing

The money saved would otherwise have been spent contracting outside test labs.

November 8, 2019

Automate and Robotize Your 100% Alloy Verification QC Procedure with Handheld XRF

Current advances in handheld XRF technology provide users with analytical results in real time.

November 8, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing