Vision & Sensors

The Capabilities of Vision Sensors

Let’s take a look at the capabilities and potential applications of vision sensors.

January 8, 2018

Cross-Industry Collaboration Can Fuel Machine Vision Innovation

Machine vision applications have grown exponentially.

January 8, 2018

3D Sensors in Machine Vision

As most players in the image processing industry know, there are several different ways to get a 3D image.

January 8, 2018

V&S HEADLINE

Industry Veteran Launches New Machine Vision Camera Manufacturing Company

January 5, 2018

Collaborative Robots: Don't Fear the Cobot

Collaborative robots, or cobots, are infiltrating factories on a global scale. But can robots and humans really work together in harmony? We asked the experts.

January 1, 2018

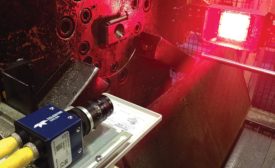

Practical VGR: Cutting-Edge Technologies and Applications

Let’s look at some of the latest vision and robotics technologies and related applications.

January 1, 2018

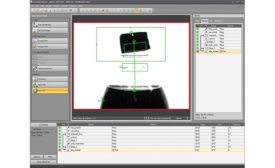

Smart Cameras in a Manufacturing Environment: Today and in the Future

The combination of dramatically improving hardware and modern software technology has made smart cameras capable, inexpensive, and easy-to-use.

January 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing