Aerospace

Luminator Aerospace ramps up backlit sign testing using colorimeters.

Read More

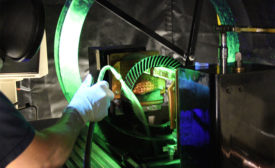

Still the One: The Enduring Attraction of Magnetic Particle Inspection

MPI can be applied to many industries and uses, ranging from roller coasters and nuclear power plants to aviation and aerospace.

July 8, 2018

DICONDE in Digital NDT Taking Hold

With the continued demand for more speed, security, and cost reductions, we expect DICONDE in Digital NDT to continue making significant progress

July 8, 2018

NDT on the Flight Line

A midair engine failure in April puts nondestructive inspections to the test

July 8, 2018

3D Printing, Big Data, 100 Percent Validation, and Other Aerospace Manufacturing Trends

Aerospace is leading the way in the IIoT, with a heightened focus on additive manufacturing, the digital thread, and lightning-fast 3D measurement and inspection technologies.

July 8, 2018

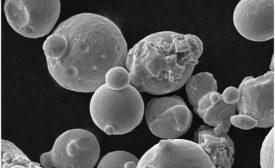

Producing Quality Metal Parts with Additive Manufacturing

Learn more about the entire 3D printing process from powder characterization to determining the best tests to qualify parts for the aerospace industry.

July 1, 2018

AS9100 Certification: Why and What Next

The standard says that people should understand the importance of what they do.

July 1, 2018

Improvements in Aluminum Aircraft Components Using X-ray Diffraction Residual Stress Measurements

Residual stresses can be controlled in the manufacturing process to produce a superior product that will last even in harsh environments.

July 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing