Aerospace

NDT in Aerospace

Eddy current testing is a crucial part of quality control.

Read More

NDT in Aerospace

Nadcap Non-Destructive Testing in Aerospace

The role of NDT is now recognized as vital to ensure the reliability of the product.

July 8, 2019

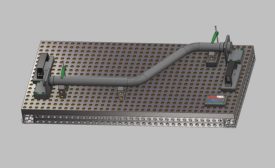

Fixturing 101: The Sky is the Limit

Fixturing tubular parts in aerospace duct fabrication with traditional vs. modular systems.

July 1, 2019

Quality Headline

Hexagon Manufacturing Intelligence Thought Leader Speaks at AeroDef Manufacturing Conference 2019

April 27, 2019

NDT Headline

Proposed Additive Manufacturing Standards Aim to Help Aerospace Industry

April 12, 2019

NDT Headline

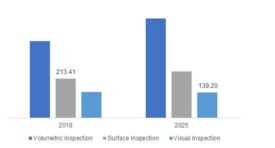

NRC of Canada, Fives Join Forces to Develop Inspection Tech for Aerospace

January 25, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing