Featured on Home Page

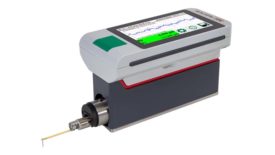

Measurement

The calibration process for surface finish units is simple but essential to the manufacturing process.

Read More

Quality 101

Understanding the Fundamentals of a Manufacturing ERP System

The common purpose of all ERP systems is to enable operational excellence, profitability and growth.

April 11, 2024

Meet the 2024 Quality Rookie of the Year: Justin Wise

Always Looking for the Next Challenge and Continuous Improvement

April 10, 2024

Column | John Vandenbemden

Climate Change and Management Standards

The integration of climate change considerations into the international standards highlights the need to acknowledge the impact it is having on our external environment.

April 9, 2024

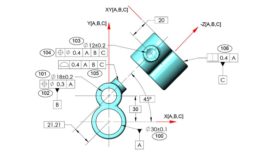

Measurement

The Definition of a Fool is a Drowning Man Who Tries to Keep It a Secret

A Story on Purchasing the Wrong Equipment and Keeping It.

April 8, 2024

Measurement

Better Measurement Data Reporting to Improve GD&T Effectiveness

ASME Y14.45-2021 Standardizes Measurement Data Content for GD&T Specifications.

April 4, 2024

Software

How to Sharpen Your FMEA Skills, Part 1

Regular use of FMEA leads to continuous improvements in processes and products. By proactively addressing potential issues, it enhances reliability, safety, and overall quality.

April 3, 2024

Vision & Sensors | Vision

Integrated, Centrally-Managed Machine Vision for Built-In Quality

If we can bridge the confidence gap between underperforming legacy vision systems and manufacturers’ needs today, the rate of adoption is sure to grow exponentially.

April 2, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing