Featured on Home Page

Test & Inspection

The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences among the available options helps determine which method will give you the best results.

Read More

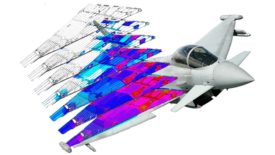

Test & Inspection

Phased array ultrasonic testing (PAUT)

Phased array ultrasonic inspection has become an indispensable tool in the aerospace industry, contributing to the safety and reliability of aircraft components.

December 31, 2023

Software

Software helps see inside a lights out process

Remote oversight supports processes that cannot by nature be closed loop controlled.

December 31, 2023

Measurement

The Crucial Role of Support and Service while Investing in Multi-Sensor Metrology Equipment

In today’s fast-paced industrial environment, the right support and service can make all the difference between a successful investment and a costly disappointment.

December 29, 2023

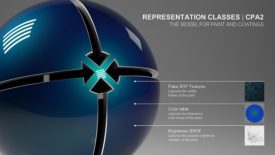

Measurement

Why Digital Workflows Require More Than Digital Color

If you only digitize color using spectral data, you are missing valuable data required for the digital design and visualization workflow.

December 29, 2023

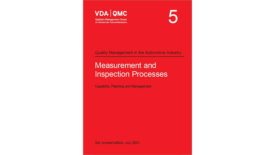

Measurement

The new VDA Volume 5 – Obligation and Opportunity

Too much measurement uncertainty leads to incorrect conformity decisions, incorrect assessment of machines and production processes, poorer process quality and thus, increased production and testing effort.

December 29, 2023

Software

AI and Automation Technologies Converge to Simplify Automated Visual Inspection

Machine vision, AI, robotics, and intelligent inspection planning technologies working in synergy help democratize industrial automation systems.

December 29, 2023

Management

Results in for the 23rd Annual Quality Spending Survey

The status of spending

December 28, 2023

Software & Analysis

Next Steps for Digitalized Quality on the Frontline

Manufacturers looking at replacing paper-based quality processes are being presented with a much broader and more effective set of technologies than ever before.

December 28, 2023

Software & Analysis

Overcoming Quality Challenges Using AI-Powered Connected Microscopy

Integration of the latest artificial intelligence technologies enable even deeper insights.

December 28, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing