Featured on Home Page

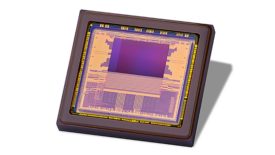

Vision & Sensors | Sensors

Manufacturers can rely on sophisticated sensors to revolutionize the way they do business, enabling enhanced quality control, improved efficiency, and increased safety.

Read More

Standards 101 | Roderick A. Munro

Using the ISO Management Systems as a Marketing Tool

Many organizations fail to realize the importance of customer perspectives on the use of standards.

September 4, 2023

From the Editor | Darryl Seland

A Phenomena Called The Mandela Effect

Rock or alligator?

September 1, 2023

Speaking of Quality | Sheri Dorman

Visual Inspection Remains Most Popular Flaw Detection Method

Visual inspection is the most popular method of determining what defect, or flaw, is acceptable or not.

August 31, 2023

Vision & Sensors | System Integration

Some Experiences Integrating Machine Learning with Vision and Robotics

Yes, there are places for machine learning in our automation world!

August 31, 2023

Case Study

Vision for the Win … Noncontact Measurement Tops Traditional CMM

A NASCAR engine typically has 857 components, so some are bound to have geometries that are problematic to measure and inspect.

August 30, 2023

Vision & Sensors | Trends

Developments in UV and IR Imaging Technology

Recent advancements in sensor and optics manufacturing technologies for UV and IR wavelengths have made imaging systems for these wavelength ranges more accessible.

August 29, 2023

ESG | Costas Xyloyiannis

Want to Keep Good ESG Data? Foster its Source

Where we really should turn the spotlight is towards the experience suppliers receive as they serve big manufacturing brands.

August 28, 2023

Management

The Essential Benefits of ISO Standards for Manufacturers

By implementing these standards, manufacturers can manage risks, drive continuous improvement, and gain a competitive edge.

August 25, 2023

Software & Analysis

Ramp up Data Management to Ramp up Production

Sustained success hinges on the effectiveness of the data management tools used to monitor and maintain product quality.

August 24, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing