Featured on Home Page

Speaking of Quality | Jim Spichiger

Why do these member leaders dedicate their precious personal time to serve?

Read More

Column | Jim L. Smith

Face of Quality: KPI Fundamentals

Focusing on the right things is the key to success.

January 15, 2022

Column | Darryl Seland

From the Editor: Environmental Influences

Accelerating evoution, delivery apps, and handicapping.

January 15, 2022

Software & Analysis

Using Simple Linear Regression For Instrument Calibration?

Learn why orthogonal regression is a better approach.

January 8, 2022

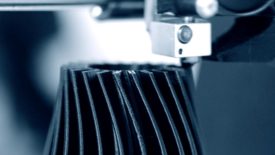

Quality 101

Quality in Additive Manufacturing

To facilitate widespread adoption of AM, it will be necessary for material property data to be shared among the design community at large instead by being held by a few large companies.

January 8, 2022

Vision & Sensors

Vision & Sensors 101: Machine Vision System Integration

Success with vision system integration requires starting right.

January 1, 2022

Vision & Sensors | Automation

Bringing AI to Visual Inspection

Adding automated decision-support for human operators helps speed visual inspection rates and improve product quality.

January 1, 2022

Vision & Sensors | Sensor Trends

Growing Sensor Sizes And Uncertainty In Pairing Lenses and Cameras

Lens and camera manufacturers need to collaborate to develop new mounting standards for the new, large sensor formats already on the market, as well as the ones that will be introduced.

January 1, 2022

Vision & Sensors | Machine Vision Trends

The Rise of Machine Vision

Machine vision is increasingly used in applications outside the factory.

January 1, 2022

Management

Spending is Back: The 21st Annual Quality Spending Survey

The 21st Annual Quality Spending Survey shows that quality professionals are looking to invest again.

January 1, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing