Featured on Home Page

TEST & INSPECTION

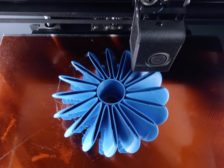

Changing Face of Additive Manufacturing Inspection

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

June 1, 2021

Inspection

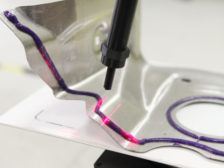

Quality and Process Control for the Dispensing Process

For Many Applications, Good Robot Programming is an Art.

May 18, 2021

Additive Manufacturing Standards

Manufacturers should be aware of the many standards for this technology.

May 7, 2021

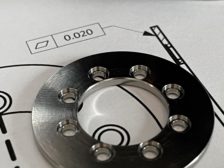

GD&T’s New Rule and What it means for Measurement

Here we will explore the implications of rule "S" and the limits/requirements of today's metrology as it is applied to these GD&T requirements.

May 6, 2021

Vision & Sensors | Cobots

Cobots for the Win

Collaborative robots helped manufacturers keep production lines running during the pandemic. They're accessible to small- and medium- sized businesses. And their simplicity just may help to shrink the skills gap.

May 5, 2021

Vision & Sensors | Machine Learning

How AI Software Enables More Accurate Quality Inspection

AI is being adopted across industries to harness the power of data and use it to make more informed decisions.

May 5, 2021

Vision & Sensors | Machine Vision 101

The Benefits of Smart Sensors & IO-Link

For many applications, good robot programming is an art.

May 5, 2021

Quality 101

Cylindrical Ring Gages: One Ring to Rule Them All

Cylindrical ring gages may be used as master gages to set variable measuring tools.

May 5, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing