Articles by Genevieve Diesing

This medical device company and essential business faced extraordinary pressure to keep up with demand while managing its own safety in a pandemic.

Read More

Leading Amid Turmoil: Quality Leadership 2021

Excellence in quality is never a small feat. This year, it was even bigger.

February 10, 2021

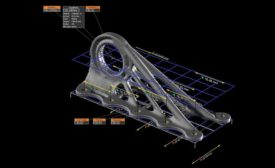

Keeping Up with Additive Manufacturing

AM production enables the creation of parts not possible with traditional technologies through new design concepts, new materials, and new applications, but still presents challenges.

December 1, 2020

Are you making this major FAI mistake?

An intelligent TDP can save time and money.

November 5, 2020

Training in the Age of COVID-19

With the virus disrupting businesses worldwide, training employees presents new challenges. Experts comment on what can be done.

November 2, 2020

A Pandemic is No Match for Industry 4.0

While COVID-19-related disruptions threatening to upend manufacturing as we know it, IIoT systems make large-scale remote work possible, improve safety and help with supply chain issues.

September 28, 2020

New Lessons in Gage Management: Don’t Overlook GR&R Testing

Strong gage management and tracking impacts a manufacturer's ability to grow, experts say.

August 31, 2020

How to Attract the Next Generation of Engineers

Here are some things organizations can do right now to keep pace with changing technology -- and help polish the field's image.

August 3, 2020

The Current State of Thickness Measurement

Optical measurement tools are picking jp steam, experts say.

June 29, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing