ARTICLES

Measurement

IoT’s real-time analytics and in-process control are making operations more precise and products more reliable.

Read More

Measurement

Precision Trends in Metrology, Part 1

The integration of 3D CAD models and advanced software algorithms are setting new standards for accuracy and efficiency in manufacturing.

May 2, 2024

Software

How FMEA is Adapting Over Time, Part 2

There’s a growing understanding that not all manufacturing or production jobs are the same, and thus, the application of FMEA should vary accordingly.

April 15, 2024

Software

How to Sharpen Your FMEA Skills, Part 1

Regular use of FMEA leads to continuous improvements in processes and products. By proactively addressing potential issues, it enhances reliability, safety, and overall quality.

April 3, 2024

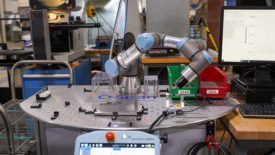

Quality in Automation | Automation

Leveraging automation for quality gains

As automation simplifies and enhances manufacturing processes, quality control staff see significant career advantages, making a shift towards more efficient, consistent, and data-driven production environments.

March 29, 2024

Measurement

Maximizing Precision: How to Care for and Integrate Your Handheld Gages

Quality control is crucial for meeting high product standards, and handheld gages are key to achieving such precision. But how exactly do these tools ensure accurate measurements?

February 19, 2024

Automation

How Modern Warehouses are Redefining Efficiency Through Automation — Part 2

Insights into how AI, IoT, and blockchain are revolutionizing warehouses, enhancing transparency, and optimizing operational efficiencies.

January 17, 2024

Automation

Skilled Workers Pivot in an Automated Age — Part 1

Transitioning from repetitive tasks to specialized roles, with training as the key.

January 16, 2024

Quality 101

How Technology and Data Analytics are Revolutionizing Auditing — Part 2

Auditing is undergoing a paradigm shift, influenced by the rapid advancements in technology and data analytics. As organizations embrace more complex, digital processes, how they’re audited is changing.

December 13, 2023

Quality 101

Auditing 101: Understanding Audits and Tips to Prepare — Part 1

Audits might seem like just another box to check off, but understanding them can help you approach them effectively.

December 6, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing