Articles by Chris Koehn

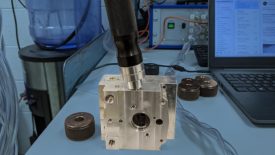

Does Air Gaging fit into a Modern World?

Air gaging is an extremely fast measurement method even when measuring difficult geometries.

September 2, 2020

Air Gaging in a High Production, Automated Manufacturing Environment

Air gaging continues to evolve and stay relevant in today’s automated world.

May 7, 2018

Quality 101

In-Process Air Gaging

The terms in-process and air gaging may not immediately sound like they go together, but there are advantages to this method.

May 1, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing