Articles by Eric Gasper

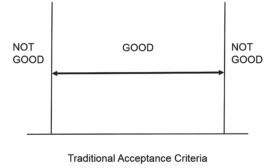

Missing the Point: Gage Variability and Operational Definitions

Clear operational definitions can prevent chaos.

April 16, 2018

Calibration and Measurement Systems: The Unsung Hero in Quality Efforts

Timely calibration of all measurement devices is critical to manufacturing efforts.

July 1, 2017

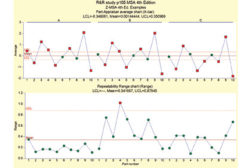

Gage R&R: The Key to Reducing Measurement Variation

A critical part of the journey toward reducing variation is developing confidence in the system used to measure the process.

November 1, 2016

Poor GR&R Percentage, Now What?

Examining the components of a GR&R study can lead to the source of greatest variation in the measurement system.

March 2, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing