Articles by Leah Pickett

Better quality is possible with IO-Link and machine learning.

Read More

New Features, Industries Elevate Laser Trackers

A big selling point of recent iterations is seamless integration into a user’s work process.

June 1, 2019

Test & Inspection

Additive Manufacturing in Production Presents Challenges, Opportunities for Quality

Applying quality control measures to additive technologies requires a holistic approach.

May 1, 2019

How a Global Manufacturer Prevents Defective Parts with SPC Software

Easy monitoring and actionable reporting are key.

April 30, 2019

Move from “Inspect and Reject” to “Predict and Prevent” with SPC Software

A senior quality leader details his approach to making significant quality improvements.

April 2, 2019

The Value of One Software for Several Types of Inspection Systems

A common software for multiple instruments, often from multiple OEMs, is ideal.

April 2, 2019

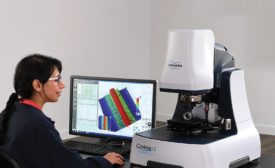

As Automation Grows, Microscopes Evolve

Industry 4.0 advances a variety of microscopy solutions.

April 1, 2019

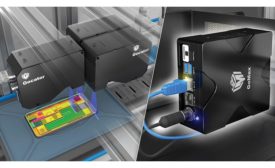

Q&A: 3D Smart Sensors, Deep Learning, and The Future of Automated Quality Control

The CEO of LMI Technologies describes how 3D sensors are integral to a new era of quality.

March 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing