Articles by Leah Pickett

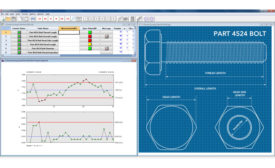

Make the right SPC software investment by asking the right questions.

Read More

How to Test Vehicles for Severe Winter Weather

A winter testing center and a quality testing company explain how they assess vehicles and components for cold weather durability.

December 1, 2018

Document Control Software: Trends and Tips

Increase productivity and quality with modern document control.

October 8, 2018

3D Printing, Big Data, 100 Percent Validation, and Other Aerospace Manufacturing Trends

Aerospace is leading the way in the IIoT, with a heightened focus on additive manufacturing, the digital thread, and lightning-fast 3D measurement and inspection technologies.

July 8, 2018

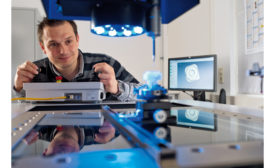

Benefits of Multi-Sensor CMMs by Industry

Aerospace, automotive, and medical device OEMs, take note.

June 28, 2018

Debunking the Myths of Fully Automated Inspection

Automated process control is more viable and less expensive than one might think.

June 5, 2018

Selecting the Right Calibration System

A calibration expert offers some suggestions.

May 9, 2018

Two Companies Share Their Secrets to Energy Efficiency, Sustainability

It's a green new world.

May 7, 2018

Choosing the Best X-Ray Solution for Your Application

Learn about industrial CT scanning, 3D XRM, and metrotomography.

April 30, 2018

QUALITY WEB EXCLUSIVE

RAPID + TCT 2018: Additive Manufacturing Goes Mainstream

April 27, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing