Articles by Ed Goffin

Vision & Sensors | Interfaces

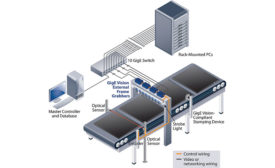

This new wave of interface design choices is significantly influenced by the electronics, mobile, and personal computing markets.

Read More

Software

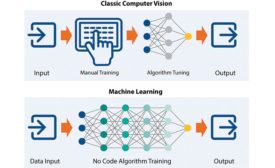

Cutting Through the Complexity of AI

At its most basic, manufacturers can consider AI as an additional tool that complements traditional machine vision.

May 22, 2024

Vision & Sensors | Trends

Making Vision and AI Easier for Users

Vision and AI can play a substantial role in reducing manufacturing costs and risk around manual and semi-automated processes.

December 1, 2023

Quality in Automation | Inspection

Protecting Your Quality With AI Visual Inspection

One of the fastest ways manufacturers can add AI decision-support into processes is with image compare.

April 8, 2022

Vision & Sensors | Automation

Bringing AI to Visual Inspection

Adding automated decision-support for human operators helps speed visual inspection rates and improve product quality.

January 1, 2022

Quality 101

I Think I Need AI! What is AI?

For most manufacturers evaluating AI, their key concerns focus on the cost and complexity of design and deployment.

October 1, 2021

Simplifying AI Deployment for Quality Inspection

Adopting a hybrid approach that marries classic and machine learning techniques for quality inspection can simplify deployment.

June 30, 2020

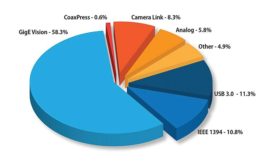

USB Brings Cost and Connectivity Advantages to Imaging

USB is the most prevalent method to connect computers and peripheral devices. Taking a survey of my desk there are a multitude of devices—a smartphone, headphones, a camera, mouse and keyboard—that rely on a USB connection.

March 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing