Articles by Thomas Parker

Test & Inspection

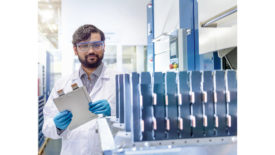

The leak testing industry has progressed to where electrolyte leak testing of every cell can be performed at production line speeds.

Read More

NDT | Leak Testing

Leak Detection’s Crucial Role in Li-ion Traction Battery Production

Manufacturers that routinely challenge their leak tightness testing process will consistently produce products with reliable performance, battery longevity and safety.

January 9, 2024

NDT | Leak Testing

Race to Mobility Sharpens Focus on Leak Testing for Li-ion Batteries and Hydrogen Fuel Cells

There are thousands of places where a battery pack or fuel cell pack can leak.

June 13, 2023

NDT | Leak Testing

E-Mobility Gives Automakers a Host of Leak Detection Challenges

EV battery cells, battery packs, electric motors and other systems modified for EV applications all require leak testing to assure both quality and safety.

June 9, 2021

Standardized Leak Testing for Lithium-Ion Battery Cells

It is Essential for Automakers.

January 6, 2021

5 Important Reasons to Check for Leaks in Battery Manufacturing

For quality, durability and safety, leak testing is critical.

July 1, 2019

The Critical Importance of Final Assembly Line Leak-Detection Testing

Finding and fixing leaks at their source is not only crucial for initial vehicle quality, but also for overall product lifecycle quality and longevity.

December 1, 2017

The 10 Most Common Errors in Leak Testing

Each year manufacturers conduct more than a billion leak tests on critical components, but there are a number of factors in that process that can hamper successful outcomes

August 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing