Articles by Greg Groth

Software & Analysis

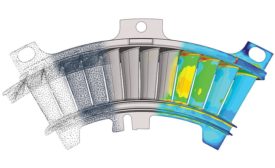

Once the model has been generated, you can use the software to analyze the model.

Read More

Software & Analysis

Reverse Engineering Software: Who? What? When? Where? Why?

Reverse engineering is used practically everywhere and in every industry.

September 1, 2022

Reverse Engineering Software 101

It is the process of converting a physical part into a digital form.

May 1, 2020

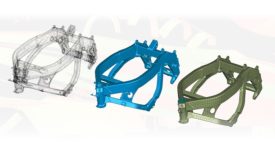

Reverse Engineering: Outputs

Learn more about these eight options using 3D scanning.

March 6, 2018

Reverse Engineering: A Basic How-To

The advancements in technology over the last 20 years have been amazing.

June 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing