Articles by Jay Arthur

Software

FMEA injects rigor into the design of products and processes that prevents defects, mistakes, errors and variation.

Read More

Software

Big Money from Small Data

Over the last 25 years, I found endless opportunities to use small Excel files to cut costs and boost profits, often by millions of dollars.

September 25, 2024

Software

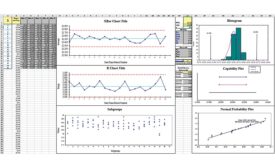

Short Run SPC for Small Batch Manufacturing

Short run charts work for both variable and attribute data.

April 30, 2024

Software & Analysis

Measurement Systems Analysis

There are many ways to assess the quality of a measurement system.

September 27, 2023

Automating Quality in Manufacturing

Automating quality in manufacturing is rarely a one-size-fits-all decision.

January 1, 2019

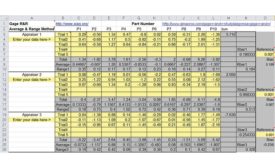

Gage R&R (Repeatability and Reproducibility)

Measurement system analysis can help you improve the quality of your products.

December 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing