Articles by Rahul Alreja

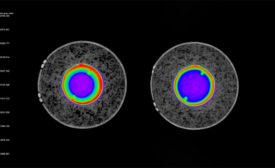

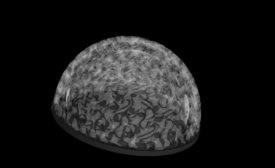

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

Read More

How 3D Printing is Changing the Medical Device Field

Being able to manufacture these devices to conform to a patient’s anatomy is a game changer.

March 2, 2020

NDT

4 Reasons Why CT is the Best Method for Medical Device Quality Inspection

CT is a huge benefit to the medical device industry and will only continue to grow.

October 1, 2019

NDT and Industry 4.0

How Industry 4.0 is affecting NDT in manufacturing, and a brief look into different technologies that affect NDT.

April 1, 2019

Dispelling the Myths of CT

Advanced robotics, faster computers, and lean manufacturing processes are all combining to improve the efficiency of manufacturing.

October 1, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing