Articles by Carl Bramley

Test & Inspection

Documenting material properties is often a key factor in quality control and R&D divisions.

Read More

Test & Inspection

Unboxing Paper Quality

In real-world use, a material only needs to be as strong as necessary, with other properties such as lightness, manufacturability and sustainability influencing its selection.

August 11, 2024

Test & Inspection

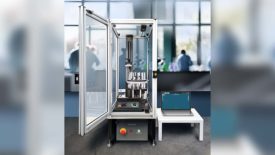

Universal applications and implementations of UTMs

A universal tester can regularly be found implementing tension and compression applications in QC and R&D environments.

April 18, 2024

Software

The Role of Software in the Quality Assurance Testing Team

In the ever-evolving landscape of manufacturing, consistency in quality is one of the bedrocks upon which reputations are built—and sustained.

March 1, 2024

Test & Inspection

Crushing it: a granular breakdown of testing what shouldn’t break down

While tensile testing garners significant attention, compression testing is equally crucial.

January 26, 2024

Test & Inspection

What Product Quality Testing is Made of

Quality materials are the route to quality products.

October 19, 2023

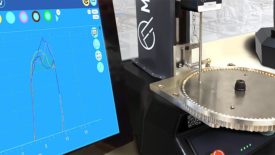

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

Tensile Testing: A Compressed “How-To” Overview

Let's start with the purpose, the practical and theory test.

November 1, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing