Home » Keywords: » universal testers

Items Tagged with 'universal testers'

ARTICLES

Management

Unchain your brain by using techniques that are proven by empirical data.

Read More

Test & Inspection

Smarter Testing Machines Require New Training Approaches

Artificial intelligence and machine learning are carving out new possibilities for data analysis and user interaction.

December 31, 2024

Test & Inspection

Universal applications and implementations of UTMs

A universal tester can regularly be found implementing tension and compression applications in QC and R&D environments.

April 18, 2024

Quality 101

Automation’s Growing Role in Universal Testing

The pandemic proved just how important universal testers are to quality. As staff shorages endure, automation is keeping this technology on point.

May 10, 2023

Test & Inspection

Reduce Testing Downtime through Quality Measures

Testing system downtime causes shipment delays, upset customers, and lost revenue.

August 1, 2022

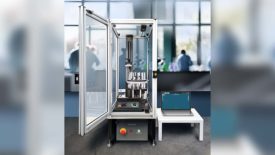

Automation: The Union of Efficiency and Repeatability

A fully-automated system requires minimal training and provides reliable results.

February 1, 2019

What to Consider When Buying a Material Tester

There is a material tester for every need.

January 8, 2018

The Universality of a Universal Testing Machine

A staple of quality control laboratories around the world, a UTM is an indispensable asset to quality and engineering professionals.

April 1, 2017

Test & Inspection

To Retrofit or Not to Retrofit: When Your Universal Testing System Gets Old

It is possible to retrofit almost any older testing system. The question is whether the investment is worthwhile.

July 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing