Home » Keywords: » noncontact measurement

Items Tagged with 'noncontact measurement'

ARTICLES

Measurement

3D scanners enable the accurate mapping of three-dimensional shapes and geometries of objects, which makes them an extremely useful tool in reverse engineering.

Read More

Test & Inspection

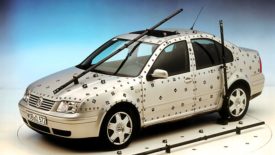

New Noncontact Technologies Meet the Challenges of the Evolving Automotive Industry

The transition from ice to electric powertrain requires a complete review of the approach to quality and process controls.

December 28, 2023

Measurement

What is Uncertainty? In Metrology, It’s Truly a Deep, Sensitive Subject

May 1, 2022

How to Successfully Establish a Correlation between Contact and Optical Surface Measurements

Contact stylus and noncontact optical can show excellent correlation.

December 3, 2020

Sponsored Content

White Paper: Introduction to Surface Roughness Measurement

October 30, 2020

The Veteran of Noncontact Metrology

Is air gaging still relevant in the 21st century?

September 2, 2020

Exploring the benefits of noncontact thickness metrology

Noncontact thickness metrology solutions have become a necessity for the manufacturing sector.

October 15, 2019

Depth Gaging from Top to Bottom

A wide variety of depth gages are available for any application.

July 8, 2018

Software & Analysis

Contact vs. Noncontact Measurement for Computer-Aided Inspection

Make the right choices to meet operational needs.

June 4, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing