Home » Keywords: » optical sensors

Items Tagged with 'optical sensors'

ARTICLES

Optical [Big, Bold, Fast] Metrology

Camera-based technologies are making strides in portable measurement for large surfaces.

April 2, 2018

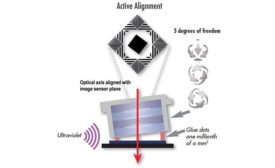

Maximizing Computer Vision Image Quality with Automated Active Sensor Alignment

Machine vision applications are seeing a shift to high quality, high dynamic range sensors.

December 1, 2017

Why Multisensor Metrology Matters

Each sensor has its own strength for particular measurement situations.

April 1, 2016

Expand Your CMM’s Capabilities

Moving from tactile and scanning systems to newer optical and laser sensor technology increases the productivity of your CMM.

August 5, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing