Home » Keywords: » surface measurement

Items Tagged with 'surface measurement'

ARTICLES

Quality 101

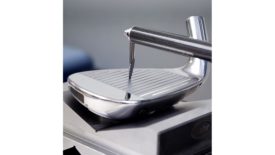

How Accurate Surface Finish Measurement Improves Product Life and Performance

Here we’ll explore the intricate relationship between surface finish and factors like friction, wear, and fatigue life.

June 10, 2024

Measurement

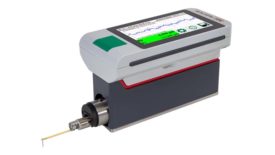

Ensuring Precision: A Guide to Calibration in Surface Finish Measurement

The calibration process for surface finish units is simple but essential to the manufacturing process.

April 12, 2024

Measurement

The Multifaceted World of Surface Measurement

Whether measuring surfaces for household products or surgical implants, surface finish measurement is necessary to optimize key product attributes, ensure safety, and comply with regulatory standards.

August 22, 2023

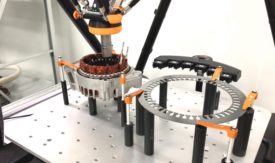

Automation Makes Surface Measurement More Reliable in a Production Environment

Automation has numerous benefits for surface finish measurement.

December 14, 2022

Quality Headline

Renishaw’s Advanced Manufacturing Roadshow Makes November stop in Michigan

October 26, 2022

Sponsored Content

White Paper: Interested in Surface Roughness Measurement? Download the Olympus Roughness Measurement Guidebook

January 28, 2021

Hidden Waviness: When Measuring Roughness Cannot Solve Quality Challenges

Roughness and waviness are dictated by each particular application.

June 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing