Home » Keywords: » Tolerancing and Dimensioning

Items Tagged with 'Tolerancing and Dimensioning'

ARTICLES

Measurement

Let's review some of the elements of geometric dimensioning and tolerancing.

Read More

Measurement

Simplifying Metrology System Selection for Medical Applications

Tips for choosing the right vision system.

October 1, 2021

Sponsored Content

Improve Your Manufacturing Processes Without Neglecting Quality and Tight Tolerances

October 8, 2019

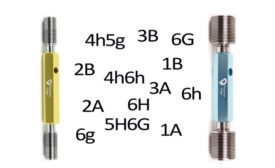

Thread Classes and Setting Plug Gages

Product tolerances and dimensions always dictate the gage tolerances and dimensions.

October 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing