Home » Keywords: » materials testing instruments

Items Tagged with 'materials testing instruments'

ARTICLES

NDT | Materials Analysis

Material analysis is a critical component of successful lightweighting strategies.

Read More

Test & Inspection

Test Methods in Combination Advance Quality for Metal Additive Manufacturing

Metal additive manufacturing is a transformational technology that brings together advanced design concepts with new materials science.

August 23, 2024

Test & Inspection

Materials Testing: Inside the Vascular Labyrinth

A trifecta of solutions for catheter testing and innovation.

August 22, 2024

Quality 101

Materials Testing: Getting It Right the First Time

Materials testing submits a material or product to a thorough, in-depth "check-up" to ensure overall quality.

January 31, 2024

NDT | Materials Testing

Extensometry in Materials Testing Explained

An extensometer is a device used to measure changes in the length of an object, or sample in the materials testing world.

April 11, 2023

NDT

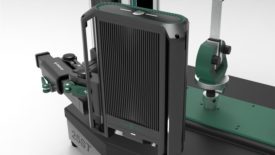

Quality 101: The Advanced Force Tester

Assuring Material Properties Through Material Testing

February 8, 2022

Sponsored Content

White Paper: Improve Your Stainless-Steel Testing with the Niton Apollo Handheld LIBS Analyzer

January 26, 2021

Handheld XRF, OES, and Portable LIBS Analyzers— Which One Is Best for Your Needs?

Understanding the limitations and differences in each of these techniques is critical when performing material analysis.

June 24, 2020

Analyzing and Reporting Tensile Data on Force Measurement Systems

Using readily available tools such as graphs, tolerances, comments, and test criteria ensures that the required tensile information is on hand when needed.

June 1, 2019

Materials Testing and the Modern Age

It’s not surprising that many of the trends we see in our everyday devices have transferred over to the world of lab equipment.

February 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing