Home » Keywords: » nondestructive examination technology

Items Tagged with 'nondestructive examination technology'

ARTICLES

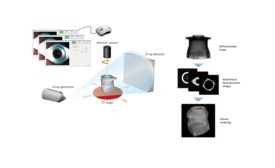

X-Ray and CT Automation Advances Make Aerospace Inspection Easier

How the advances are benefitting aerospace engineers with increased flexibility, improved image quality, better reporting and data storage capabilities.

July 1, 2020

Easing the Inspection Task

Recent developments in various NDE modalities are making inspection more accurate and faster while providing data that is easier to interpret.

June 10, 2020

Looking Internally with Computed Tomography

Users from electronics manufactures to paleontologists see benefit of nondestructive inspections.

June 29, 2018

What You Need to Know When Selecting an Ultrasonic Thickness Gage

It’s important to know beforehand what the instrument can and cannot do.

October 31, 2017

NDT - Ultrasonics

Market Analysis

Where is The Ultrasonic Nondestructive Test Equipment Market Headed?

June 12, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing