Home » Keywords: » ultrasonic inspection

Items Tagged with 'ultrasonic inspection'

ARTICLES

NDT | NDT in Aerospace

As the number of flights is expected to keep increasing over the years, flaw detection is critical to safe air travels.

Read More

Test & Inspection

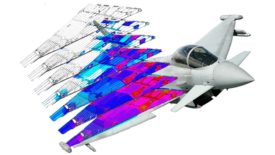

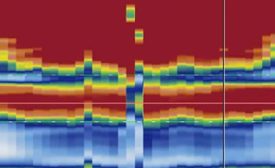

Phased array ultrasonic testing (PAUT)

Phased array ultrasonic inspection has become an indispensable tool in the aerospace industry, contributing to the safety and reliability of aircraft components.

December 31, 2023

NDT

The Advantages of Phased Array Technology

When evaluating welded tubes.

February 15, 2021

Using Phased Array UT for Austenitic Weld Inspections

How the latest phased array ultrasonic testing tools and techniques allow more productive NDT.

June 1, 2018

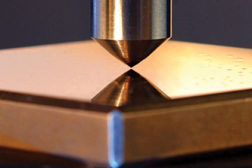

Automated Inspection of Critical Aerospace Components and Structures with Complex Geometries

As aerospace parts are becoming more and more complex, fabrication and materials automated inspections will become the only viable inspection method.

July 1, 2017

NDT - Phased Array

Parallel Phased Arrays to Achieve High-Speed Inspection

Automation and parallel phased array systems are being used to meet challenging inspection and production requirements.

October 10, 2013

NDT - Ultrasonics

Market Analysis

Where is The Ultrasonic Nondestructive Test Equipment Market Headed?

June 12, 2013

Market Analysis

Hardness Testing: Market Analysis 2013

Market upbeat despite facing headwinds.

June 10, 2013

Quality 101

Ultrasonic Flaw Detectors...And Beyond

A history of the discovery of the tools of nondestructive technology.

April 19, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing