Home » Keywords: » mechanical testing

Items Tagged with 'mechanical testing'

ARTICLES

Test & Inspection

A simple tensile test can be used as a quality control measure to ensure the materials meet internal criteria, or for comparison purposes.

Read More

Destroying Materials is Critical to Saving Lives

Recent developments and improvements in testing equipment, sensors, and knowledge have led to a significant increase in high speed and high rate material testing efforts.

August 3, 2020

The Role of Mechanical Testing in Additive Manufacturing Quality Assurance

Get answers to some of the most commonly asked questions about testing additive products.

June 27, 2020

Mechanical Testing of a Stent: From Component Selection to Deployment Techniques

With stents and other implantable medical devices, the cost of failure can be extremely high.

June 8, 2018

Mechanical Testing of Automotive Materials and Components

Testing the performance of components is critical to many automotive suppliers in a quality control aspect—and hugely important for research and development of new products.

October 10, 2017

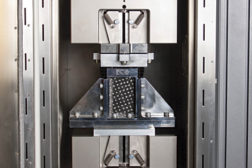

Tensile Testing Machine Basics

Learn more about testing solutions available today.

October 1, 2015

Quality 101

Mechanical Testing of Composites

The mechanical testing of composite materials involves a range of test types, a plethora of standards, and the need to condition and test in a variety of different environments.

July 1, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing