Home » Keywords: » torque testing

Items Tagged with 'torque testing'

ARTICLES

Test & Inspection

Here are a handful of example quality control processes that focus on the measurement of torque, with emphasis on sectors where testing is highly regulated, FDA 21CFR Part 11 being a prime consideration.

Read More

Test & Inspection

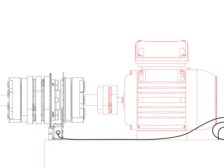

Getting The Most Out Of Torque Testing

First and foremost, it's important to understand what a torque transducer is before implementing a test.

November 1, 2021

Quality 101

TORQUE GAGES

Experts discuss the current torque testing landscape and what’s ahead.

May 1, 2016

Measuring the Barely Measurable

Where torque forces to be measured are very small, precision at every point in the testing system is essential.

August 11, 2014

Test & Inspection

Torque Testing Success

Unlock the potential of automated product torque testing.

June 4, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing