Home » Keywords: » ANSI

Items Tagged with 'ANSI'

ARTICLES

Column | John Vandenbemden

Military standards came from a need for a sampling system that did not require 100% inspection for use in testing munitions and other destructive tests.

Read More

Vision & Sensors | Robotics

What You Need to Know About Robot Safety Standards

A Q&A with A3’s Carole Franklin

November 13, 2023

Column | John Vandenbemden

Volunteers Needed for TAG 69

If you have knowledge, expertise, and willingness to share, come join us on US TAG 69.

September 18, 2023

Test & Inspection

Measurement And Inspection Standards

As technology continues to evolve, it will take a lot of work from the standards community to help the industry keep pace with news tools for new manufacturing methods.

May 1, 2022

NDT

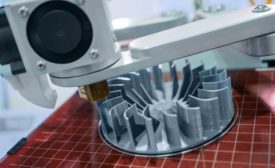

Materials Testing Standardization in Metal Additive Manufacturing

Even with the use of existing standards, several notable gaps remain.

October 1, 2019

INDUSTRY HEADLINE

NSF International President and CEO Elected Board Chair

February 3, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing