Home » Keywords: » Camera Link

Items Tagged with 'Camera Link'

ARTICLES

Vision & Sensors | Machine Vision 101

Although more than two decades old, camera link shows no sign of slowing down.

Read More

Avoid Costly Missteps When Selecting a Machine Vision Interface—Now and in the Future

Selecting a machine vision interface represents a long-term investment and is always application-specific.

January 1, 2019

Why the CLHS Interface is a Boon to Manufacturing

Of all the machine vision standards available on the market, the Camera Link HS (CLHS) protocol leads in reliability, cost, and throughput.

September 4, 2018

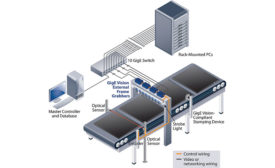

Ethernet Evolution – 10 Gigabit Ethernet

With 10 gigabit ethernet, higher bandwidth is added to the familiarity and reliability of gige vision cameras and twisted pair cabling

September 1, 2017

The Future of Machine Vision Standards

Because of the large scope of machine vision, there can be no true winner of this battle of standards.

July 1, 2017

Vision Interfaces 101

As resolution and frame rates increased over time, so have the requirements for camera interfaces.

September 1, 2016

Don’t Come Up Short

LEARN HOW TO SELECT APPROPRIATE CABLES FOR YOUR PROJECT.

September 8, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing