Home » Keywords: » surface metrology

Items Tagged with 'surface metrology'

ARTICLES

From the Editor | Darryl Seland

Choosing your words and everything else, wisely.

Read More

How to Successfully Establish a Correlation between Contact and Optical Surface Measurements

Contact stylus and noncontact optical can show excellent correlation.

December 3, 2020

Hidden Waviness: When Measuring Roughness Cannot Solve Quality Challenges

Roughness and waviness are dictated by each particular application.

June 1, 2020

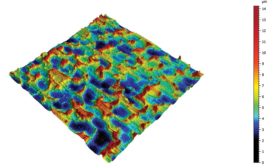

How to Make the Right Choice between 2D vs. 3D in Surface Metrology

With the advent of new processes and materials, surfaces have an increasingly technical function.

August 1, 2019

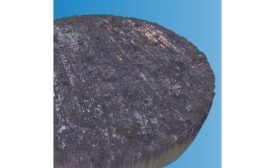

Fully Characterizing Brake Pad Materials to Improve Performance and Lower Development Costs

Combining benchtop mechanical testing of smaller brake material samples with rapid 3D surface metrology makes it possible to analyze results more quickly than ever before.

September 1, 2018

INDUSTRY HEADLINE

Michigan Metrology Announces Short Course to Further the Understanding of Surface Texture and Tribology

July 2, 2018

Quality 101

Measure Your Needs for the Proper Height Gage

Selecting the right gage for the right job.

October 30, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing