Home » Keywords: » Vickers hardness test

Items Tagged with 'Vickers hardness test'

ARTICLES

Test & Inspection

The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences among the available options helps determine which method will give you the best results.

Read More

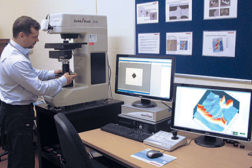

Automation Drives Vickers Hardness Testing Into the 21st Century

The Vickers test is well suited to characterization of materials with extremely hard surfaces.

February 2, 2015

Test & Inspection

Common Problems in Microhardness Testing

By using properly maintained and calibrated equipment, trained personnel, and appropriate testing environments, these problems can be minimized.

May 1, 2014

Case Study

Hardness Testing Assures Quality in Advanced Materials

Hardness testing is often the best way of establishing that components will survive and perform in their intended applications.

May 1, 2014

Test & Inspection

The Vickers Hardness Test

Over the past 90 years, the Vickers test has proved to be an all-around respectable performer in a wide variety of applications, some of which the inventors never dreamed possible.

November 1, 2013

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing