Home » Keywords: » force testing

Items Tagged with 'force testing'

ARTICLES

Quality 101

Compression testing is a vital process in quality control, helping manufacturers evaluate the strength, durability, and stability of materials.

Read More

Test & Inspection

Determining if Force and/or Material Testing is Right for your Application

Your choice can be simplified by knowing what kind of information you need to collect.

March 9, 2023

NDT | Force Testing

Measuring Force Data in Extreme Conditions

Manufacturers want more data in the product development process to create better products, and they need solutions that can perform in any condition.

February 15, 2023

Quality 101

Force Testing Ensures Syringe QC During Design, Manufacture and Application

Uniaxial force testers have the advantage of performing both material tests and application demonstrations to ensure that quality products are made.

June 15, 2022

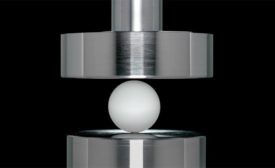

NDT | Compression Testing

Squeezing the Most Out of Compression Testing

The data derived from compression testers can be helpful throughout the life cycle of a product.

August 15, 2021

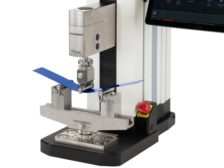

Test & Inspection

Navigating Supply Chain Challenges with Force Testing

Recent advancements in force measurement equipment allow quality professionals to better handle unpredictable testing demands.

May 5, 2021

Materials Testing

Force Testers Vs. Material Testers

Force testers and material testers have expanded into industries such as medical, plastic, and aerospace to assure that strict product performance and reliability standards are met.

April 8, 2021

Peel Applications

Lengthwise force testing for adhesives and interlocking materials.

February 8, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing