Home » Keywords: » surface finish

Items Tagged with 'surface finish'

ARTICLES

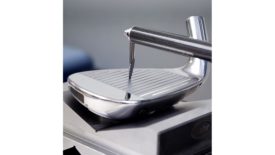

Measurement

Whether measuring surfaces for household products or surgical implants, surface finish measurement is necessary to optimize key product attributes, ensure safety, and comply with regulatory standards.

Read More

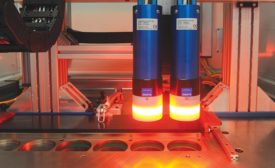

Form Measurement in the Electric Vehicle Industry

Form measurement is the ability to identify the shape, size and location of specific 2D or 3D features.

June 1, 2020

The 10 Commandments for Selecting and Using Air Gaging

When followed properly, these will provide a highly successful inspection system.

August 1, 2017

Optical Metrology Sees More

No other measuring method is capable of evaluating so many data points as quickly and as precisely as optical systems can.

May 1, 2017

Pushing the Limits of Air Gaging—And Keeping Them There

Air gaging gives you a fast measurement device that provides superior reliability in the dirtiest shop environment.

July 2, 2015

A Different Slice of Surface Finish

Learn more about surface characteristics.

September 5, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing